Expansion joint profiles

.Expansion joint profiles are the most important products

, an Expansion joint is an opening within a structure, designed to absorb thermal movements

.seismic movements and wind forcing

.The size of expansion joints in a building is usually determined by the structural engineers

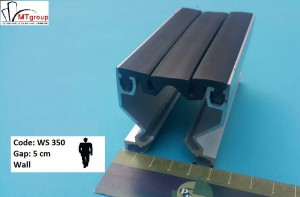

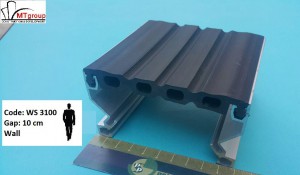

.MTgroup produce a wide range of expansion joint profiles for interior and exterior applications

.We designed also insulation tapes for places with water leakage risk

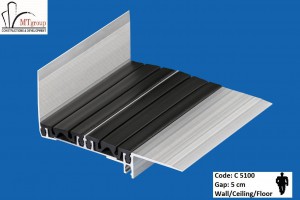

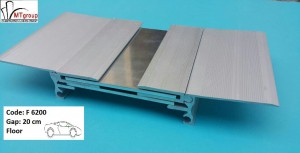

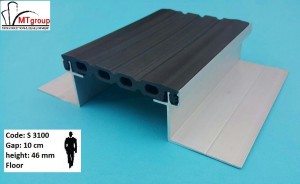

We considered load-bearing capacities so some profiles can be applied for heavy vehicles or cars

.depending on the gap inquired

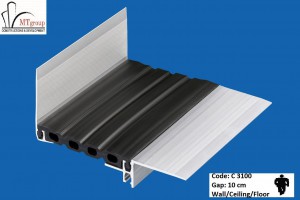

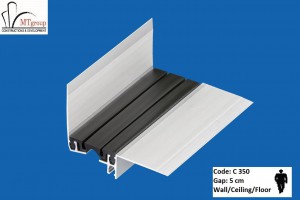

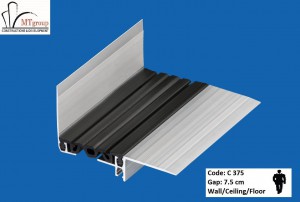

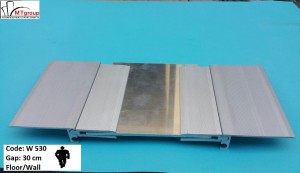

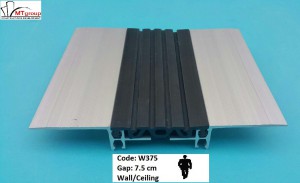

MTgroup covers (Multi profiles) provide simple solutions to cover interior or exterior floor

,. wall and ceiling joints

.Multi profiles have a special installation that MTgroup specialties have designed

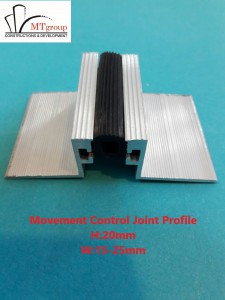

Also, we designed movement control joint profiles for absorbing tile movement and commonly

.used for easy installation

Over 15 years in the business is proof that we stand behind those words. MTgroup has set an

, industry benchmark with our combination of highly skilled engineers, manufacturing processes

.and drafting designs

We customize Expansion joint profiles to fit the needs of your project. At MTgroup we are dedicated to

.bringing you the highest quality products at competitive prices

Our services include :

estimating

custom product design

technical assistance

sales

manufacturing

shipping

marketing

drafting

drafting

follow up

training

export services

.Let us be an integral part of your next project.

.we say MTgroup is your trust in your construction and industrial projects

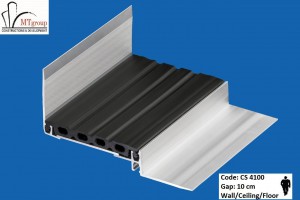

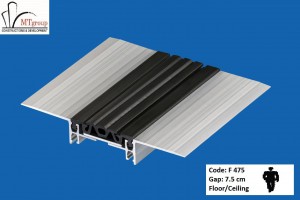

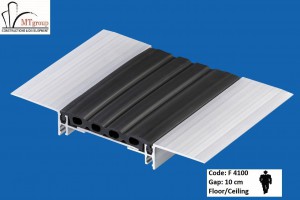

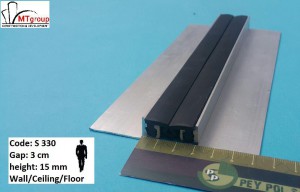

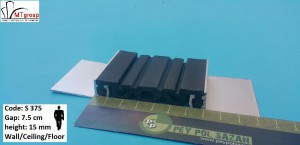

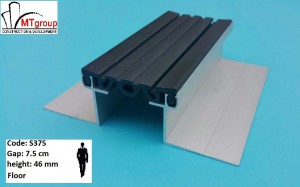

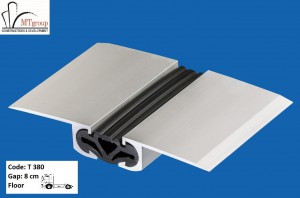

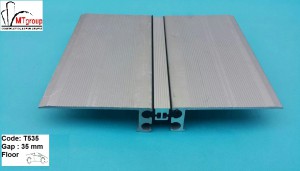

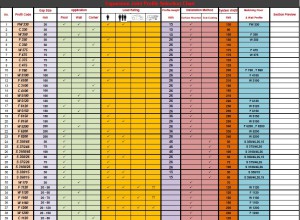

MTgroup Expansion Joint Profiles Selection Table

MOVEMENT JOINTS PROFILES

Movement joints are an integral part of any tile assembly. The various components of a tile

assembly (tile, mortar, substrate, etc.) expand and contract according to each component’s

intrinsic physical properties with changes in moisture, temperature, and loading, resulting in

internal stresses.

Furthermore, structures that restrain the overall expansion of the tile field (walls, columns, etc.)

cause stress buildup within the system. If the aforementioned movements are not

accommodated through the use of movement joints in the tile field and at restraining

structures, the resulting stresses can cause cracking of the grout and tile and

delamination of the tile from the substrate.

Thus, movement joints are an essential component of any durable tile assembly.

MTgroup-Systems’ prefabricated movement joint profiles accommodate movement and protect tile edges, resulting in a permanent, maintenance-free installation. The family

of MTgroup profiles prefabricated movement profiles include a variety of shapes sizes, and materials to suit different applications.

Application and Function

►Mortar Bed Joint Profiles – Type 1

MTgroup joint profiles (type1) are designed to Provide movement joints in tile

installations that are set in a mortar bed (e.g., ceramic tile, natural stone,

pavers, and agglomerate tile). These profile systems are placed to produce

individual fields in the assembly and feature flexible central zones to accommodate

movement.

MTgroup mortar bed joint profiles may also be inserted in saw-cut joints or wider

joints; for example, in the case of renovations. The remaining joint between the

tile and the profile must be filled completely with grout or epoxy. The side

sections of the profiles, made of rigid PVC, protect the edges of the adjacent

covering against mechanical stresses caused by industrial traffic.

However, where heavy mechanical stresses are anticipated, limitations of the

PVC as edge protection must be considered.MTgroup joint profiles (type1) is

available in three different heights and feature stable serrated sidewalls made

of rigid PVC and a central movement zone made of soft PVC. The side sections

are made with environmental color. Since the side sections are partially exposed

at the surface, also is intended mainly for industrial use.

►Surface Joint Profiles – Type 2

Surface joints must be placed within the tiled surface regardless of substrate

conditions. They provide stress relief from movements in the tile field due to

thermal and moisture expansion/contraction and loading.

MTgroup Systems offers a wide variety of prefabricated, maintenance-free

surface movement joint profiles, suitable for applications ranging from residential to heavy commercial.

MTgroup joint profiles (type2) features made of aluminum, which is secured

in the mortar bond coat and provide edge protection for adjacent tiles.

Material Properties and Areas of Application

Anodized aluminum profiles feature an anodized layer that retains a uniform appearance during normal use. The surface, however, is susceptible to scratching

and wear and may be damaged by grout or setting material. Therefore, these materials must be removed immediately. Otherwise, the description regarding

aluminum applies. textured color-coated aluminum is pretreated (chromated)

aluminum that is color-coated with a polyurethane powder coat. The coating

is color-stable, UV-resistant, and suitable for exterior use. Protect the profile

against abrasion or scratching. Thermoplastic rubber inserts are highly resistant to chemicals and can withstand chemical stresses typically encountered in tile

coverings. The insert is resistant to aging, weather, UV-rays, and ozone within

a temperature range of -76 °F (-60 °C) to 212 °F (100 °C).

Thermoplastic elastomers can be connected by welding if profiles are joined to

produce longer lengths.

MTgroup Flex Sealing Tape (named: R-seal )

For watertight expansion joint systems

MTGFlex Sealing tape ( R-seal ) is made from rubber and used for waterproofing expansion joints. Economical, easy, and simple to apply,

very flexible and elastic, so rubber membrane is ideally suited for sealing of

expansion joints.

Also, We designed PPS Flex for bonding and joining MTGFlex tape.

► For the vertical and horizontal applications in the expansion joints in constructions.

► Excellent movement in the longitudinal and lateral directions.

► Permanently complete sealing expansion joints.

► Excellent connection with any other waterproofing systems.

► Excellent resistance rays, UV, fatigue, and water.

► Superb resistance against high temperatures and low.

► Can be used on all horizontal and vertical surfaces.

► Excellent resistance against vapor.

► It has high tensile.

► It is durable.

► Applicable for sealing expansion joints places (roof, kitchen, terrace, pool

, and other similar locations)

► The rubber tapes in widths 50,40,30,20 cm and a thickness of 2 mm and

length of 25 m are produced.